Metal-Organic Frameworks (MOF) for Chemical and Biological Protection

MOFs - Metal-Organic Frameworks

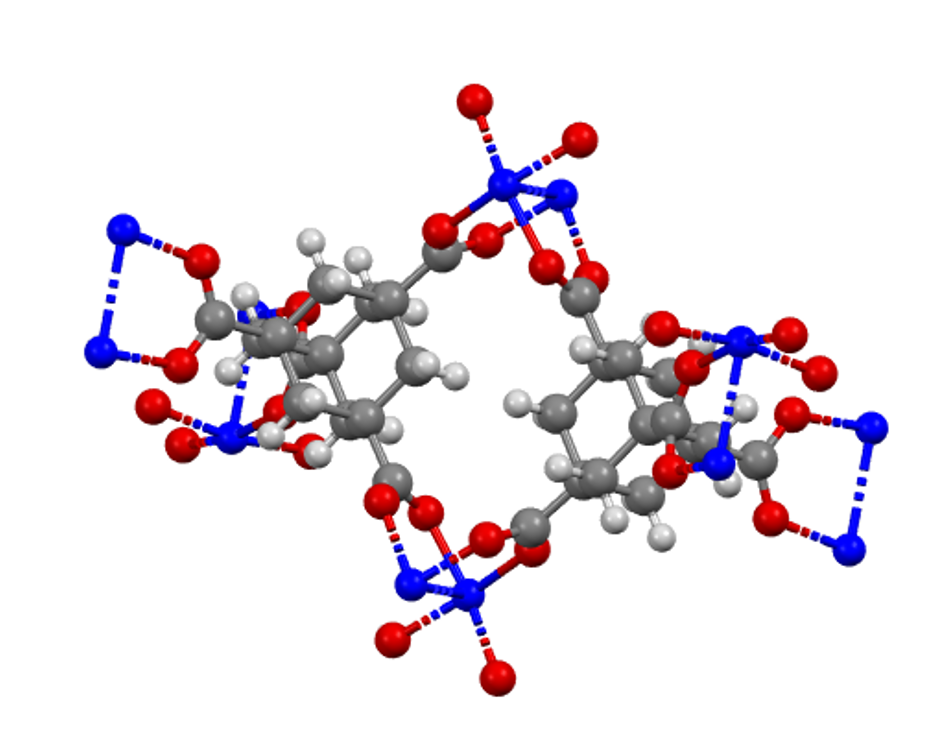

MOFs, or metal-organic frameworks, consist of metal ions or clusters connected by organic molecules called linkers. They form a unique cage-like structure with empty spaces or pores. This allows MOFs to have a large surface area and high porosity, giving them unique properties and potential applications in various fields. The choice of metal ions and organic linkers used in the synthesis of MOFs can be tailored to achieve specific properties and functionalities. This tunability allows MOFs to be engineered for different applications, such as gas storage, separations, catalysis, drug delivery, sensing, and more. Because of this tunability, MOFs have gained significant attention in scientific research and industrial applications. However, large-scale production is challenging, limiting their availability in large quantities.

Tetramer MOF Programs

For the last several years, Tetramer has engaged in several projects made possible by the unique properties of MOF technology. Our team is tackling chemical and biological defense applications in fabrics to protect soldiers and civilians with the Department of Defense. In addition, through Department of Energy funding, our team has investigated water purification technologies to remove dangerous heavy metals and the development of a cost-effective manufacturing process for MOFs used in the reprocessing of spent nuclear fuels.

Our team has gained deep expertise in the area and welcomes further collaborations in this exciting and growing space.

Ongoing MOF Projects

In addition to our proprietary industrial partnerships, the US Department of Defense Joint Science and Technology Office for Chemical and Biological Defense is funding continued development of Tetramer MOF technologies.

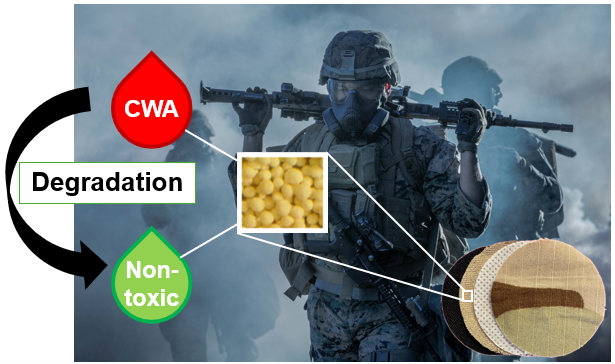

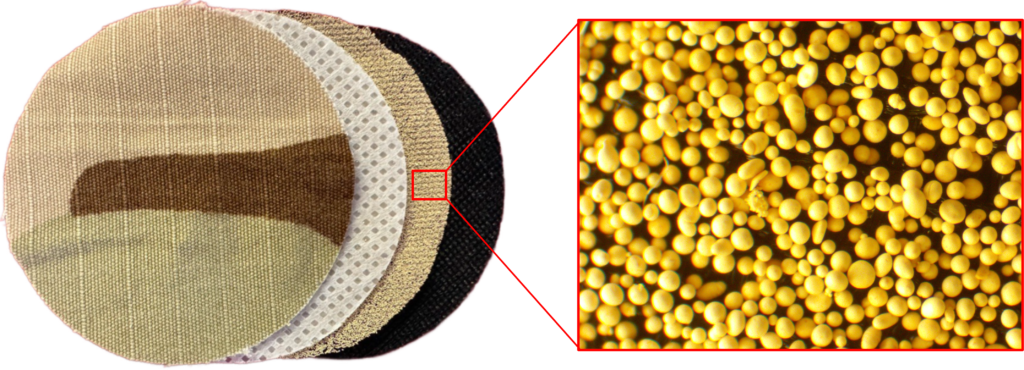

Adsorbent Materials with MOFs: Protecting soldiers facing chemical warfare agents

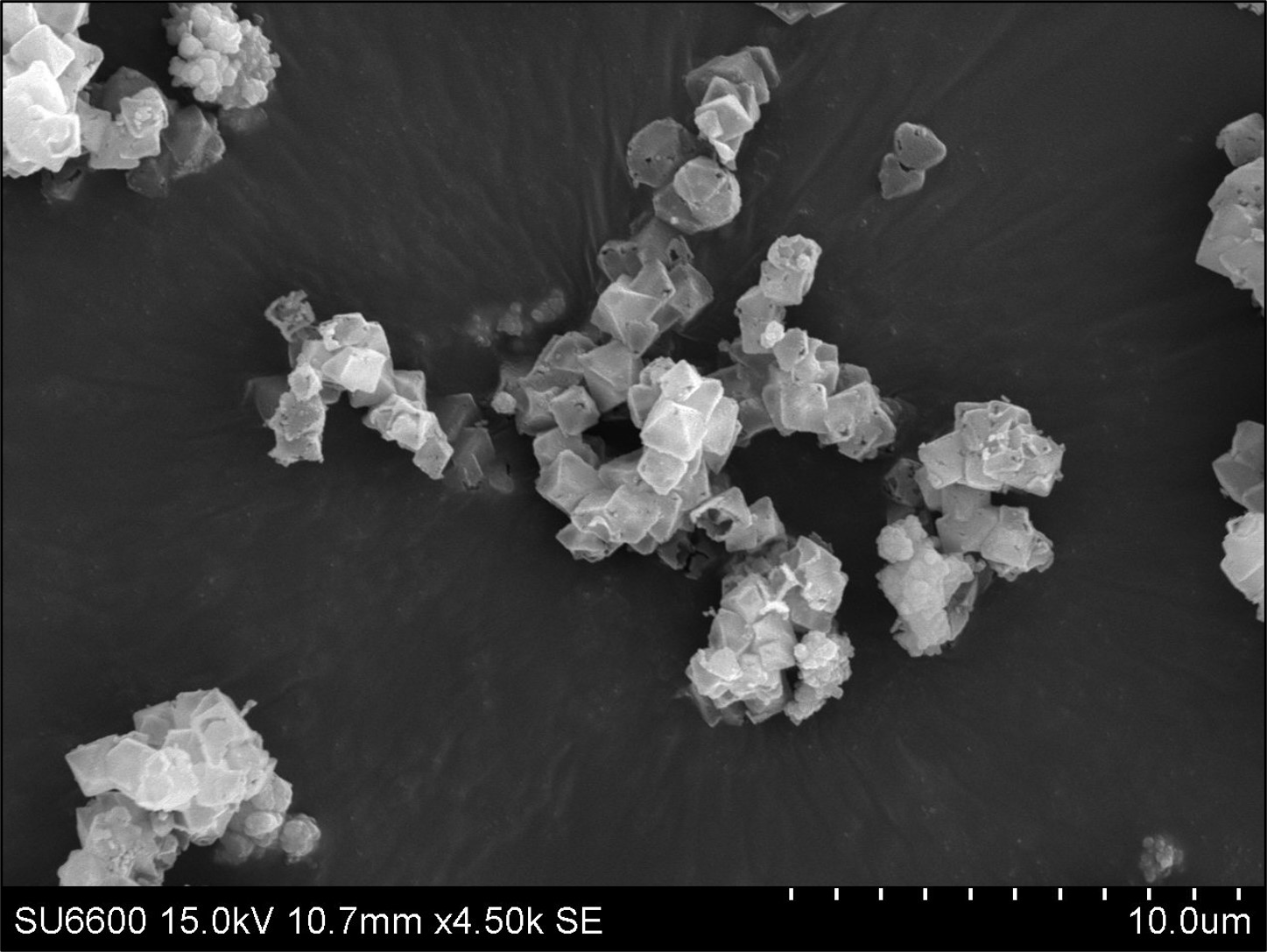

Funded by the Department of Defense Joint Science and Technology Office for Chemical and Biological Defense through a Phase I and Phase II SBIR program, Tetramer’s MOF team developed a novel adsorbent material to be used in protective suits for soldiers that encounter chemical, biological, radiological, and nuclear (CBRN) threats. Tetramer bead technology consists of metal-organic frameworks (MOFs) that are incorporated into garments to adsorb and degrade chemical warfare agents (CWAs) into non-toxic compounds on contact.

For warfighters facing the threat of chemical warfare agents, confidence in protective gear is critical. Heather Lange, Tetramer Senior Research Scientist and Principal Investigator said, “Tetramer’s material not only adsorbs the chemical threat but degrades it as well, significantly increasing efficacy of the suit to improve the physical safety and the psychological performance of the soldiers. This material has applications in protective suits as well as gloves, boots, and even gas masks.”

APPROVED FOR PUBLIC RELEASE

Using these beads in place of current materials is expected to better protect warfighters while also increasing breathability and comfort to enable extended use times and reduced logistical burden on forward operating units. Additionally, these materials are suitable for use in protective wear for civilian industrial applications such as HAZMAT suits.

Lab to Battlefield

In 2025, Tetramer was awarded a $12.5MM 5-year Other Transaction Authority (OTA) program through the Countering Weapons of Mass Destruction (CWMD) Consortium managed by Advanced Technology International (ATI) and on behalf of Defense Threat Reduction Agency (DTRA). This funding supports the integration of Tetramer’s advanced Metal-Organic Framework (MOF) bead technology (developed in the SBIR programs described above) into protective fabrics designed to safeguard soldiers operating in chemical, biological, radiological, and nuclear (CBRN) environments. Read Press Release Here

“This project represents a significant step forward in integrating cutting-edge materials into protective gear,” said Heather Lange, Principal Investigator at Tetramer. “Our MOF beads are capable of adsorbing and neutralizing CWAs and TICs on contact, offering a new level of defense for those operating in high-stakes environments. We are thrilled to collaborate with industry leaders to create fabrics that combine functionality, comfort, and safety, addressing the complex needs of today’s warfighters.”

Adam Haldeman, Tetramer’s Vice President of Research and Development, commented on the development of the technology, “This award represents a critical step in advancing a technology that began as a concept at Tetramer over five years ago. This support will allow us to transition it into field-ready prototype garments—delivering protection to the warfighter in the most demanding operational environments.”

Building on these opportunities, Michelle DiMaio, CEO of Tetramer Technologies, emphasized the broader impact, “This OTA project marks an important starting point focused on enhancing military protective fabrics, but it’s just the beginning. We’re excited to pursue new opportunities and partnerships that will expand the use of this versatile material across a range of military and industrial applications.”

Collaborators

The project benefits from Tetramer’s partnership with several key collaborators. Together, these partners strengthen the program’s foundation and ensure the transition of high-performance materials from laboratory innovation to field-ready protection.

Kappler Inc., a leader in protective suit manufacturing will leverage their extensive experience in developing and producing specialized protective apparel to ensure that Tetramer’s MOF bead technology will be incorporated into low-burden, high-performance PPE that meet the rigorous demands of soldiers operating in CBRN environments.

Advanced Functional Fabrics of America (AFFOA) will provide guidance for fabric materials best suited for integration of Tetramer’s MOF bead technology.

Dr. Chris Cole, Clemson University Professor Emerita in Materials Science and Engineering and Clemson Textiles Lead, will lend expertise in textile evaluation and fabric design.

Battelle will conduct agent testing to validate the performance of the protective fabrics under realistic threat conditions.

Kappler Inc. is a small business headquartered in Guntersville, AL. We have been protecting Military Personnel, First Responders and Industrial Workers with chemically protective clothing since 1976. Additionally, we provide custom research and development for projects requiring chemical barriers, prototype services for product innovations, contract manufacturing for product scale-up, specialty, testing services, and product specific training. Kappler is a woman-owned small business (WOSB) and WE: are ISO 9001-2018 certified.

M2DCON is dedicated to serving those who protect and serve others by providing innovative and proven decontamination and collective protection consumable products and equipment. Our team has multiple decades of experience in research, development and use of chemical/biological decontamination and related collective protection products. With more than 25 patents and extensive collaborative research with industry leaders and government laboratories, including U.S. Army CBC (formerly known as ECBC), U.S. Air Force AFRL, Dugway, etc., M2DCON has proven experience developing and manufacturing state-of-the-art decontamination equipment, chemistries and consumables to meet the most challenging requirements.

Industry Memberships

Developing MOF Manufacturing Methods: Cost-effective and continuous production of MOFs

Working under a Department of Energy Phase I award, Tetramer developed a method for the cost-effective syntheses of MOF structures suitable for use in a variety of applications, including nuclear waste separations activities. The Tetramer MOF manufacturing process developed in this program has achieved exceptional results including:

- Greater than 2X increase in yield (%) compared to MOF yields using published synthetic methods

- Space Time Yields (STY) of the MOF Syntheses 8-18X that of published synthetic methods

- Reduced equipment requirements (now compatible with stainless steel)

- Successful recycling of unreacted starting materials to further reduce MOF cost (up to 90% yield with recycled starting materials)

- Xe/Kr uptake and selectivity corresponding to published values

Phase I: METAL-ORGANIC FRAMEWORK MANUFACTURING TECHNOLOGY – DOE Phase I SBIR: DE-SC0022740 Topic(Subtopic): 38(a)

Collaborators for Further Development of MOF Manufacturing Technology

Building on the above successes in Phase I efforts, Tetramer is interested in collaborations to continue the development and optimization of the MOF manufacturing process.

Developing Filtration Materials with MOFs: for selective capture of contaminants and/or valuable metal ions from water

Funded by a Department of Energy Phase II award, Tetramer is working on the development and commercialization of a filtration material that can remove heavy metal toxins from industrial waste streams before they are released into the environment.

As the use of electronics and other technologies that rely on heavy metals has increased, more heavy metal contaminants make their way into our environment. Even in small amounts, contaminants such as lead, mercury, cadmium, arsenic, and chromium can be dangerous to both aquatic life and humans. Current water treatment methods are not selective for these specific dangerous metals, lack operational efficiency, and require frequent replacement when they become overloaded. To overcome these issues, the Tetramer team is working under DOE Phase II funding to develop new tailorable materials that can selectively adsorb and remove toxic heavy metal ions from water.

“Removing contaminants from drinking water is a major problem worldwide. Tetramer’s efforts to produce filter media that are selective to heavy metals will add one more tool for producing clean water and can aid in improving clean water access to millions of people,” said Tetramer CEO, Jeff DiMaio.

Novel Hybrid Porous Materials for the Selective Capture of Contaminants and/or Valuable Metal Ions from Water

Department of Energy: https://science.osti.gov/sbir/Awards (This award is found under2022 Phase II, Release I Awards)

MOF Collaborations Welcome

Tetramer is open to partnership opportunities with other groups to advance the development of our ongoing programs.

In addition, materials not yet ready for full-scale production may be available in research quantities under Non Disclosure Agreements (NDA) and/or Materials Transfer Agreements (MTA).