Analytical Capabilities &

Investigative Analytical Services

Characterization is essential to chemistry and materials research and development.

Tetramer maintains a world-class suite of analytical and test equipment for thermomechanical, optical, and chemical analyses staffed by full-time analytical chemists. A deep understanding of synthetic organic chemistry, materials science, optical materials, paints and coatings, advanced membrane technologies, solid state physics and more enable the comprehensive study of unique materials challenges.

Our analytical capabilities support both our research and development and manufacturing programs with Industrial, Government, and New Venture partners as well as those seeking Investigative Analytical Services.

Learn how Tetramer can solve your materials-related challenges

Our Expertise

More than just analytical testing services, we work with you to bring clarity to your complex materials and processing challenges.

We specialize in:

-

Root Cause Analysis

-

Process Characterization

-

Method Development and Validation

-

Deformulation Study

-

Quality Evaluation

Our Approach

Tetramer Investigative Analytical Services works to develop cooperative relationships with customers to achieve the most complete understanding of your technical challenges. This interactive approach enables a thorough identification of factors affecting your materials and allows for the development of strategies for improving the reliability and profitability of your products. Tetramer has a proven track record for developing analytical methods to provide more complete and meaningful data sets for problem solving.

Whether you are trying to understand a failure mechanism in an adhesive, why a coating is blistering, or how to better characterize a material for patent protection, a call to our Analytical Chemists will be worth your time.

Our Capabilities

Chemical Characterization

- GC Systems (2)

- HPLC

- GPC (2)

- GC/Mass Spectrometer

- Acid/Base Auto-Titrators

- Karl Fisher Titrator

Thermomechanical

- TGA (2)

- DSC (2)

- Simultaneous DSC/TGA

- Photo-DSC – UV Curing Kinetics

- TMA – (-150 to 600 °C)

- DMA – (-150 to 600 °C)

- Mettler Dropping Point Tester

- Rheometer –Cone and Plate

- Rheometer –Spindle

- Melt flow Indexer

- Kinematic Viscosity Tester

Spectroscopy

- FTIR – Transmission and ATR

- UV-Vis Spectrometer

- Fluorescence Spectrometer

- Refractometer

- Fiber Spectrometers

- NMR

- X-Ray Diffractometer

- Atomic Absorption Spectrometer (AAS)

Microscopy

- Optical and Fluorescence Microscopes with Cross Polarization Capability

- SEM

- TEM

- EDS

- XPS

- FIB

Physical Testing/Sampling Prep

- Helium Pycnometry

- Needle Penetration Testing

- Hardness Testing

- Gardner Liquid and Color Standards

- Minolta Colorimeter

- Dynamic Contact Angle Analyzer

- Instron Universal Measurement System

- Static and Dynamic Particle Size Analysis

- ASTM Adhesion Testing

This is not an exhaustive list of our in-house analytical characterization equipment and capabilities. To receive a more detailed listing, please contact our team.

Investigative Analytical Case Study

A manufacturer of a functional coating material needed help understanding the key compositional differences between their material and a competitor’s.

The Tetramer Analytical Services lab was approached by a manufacturer who produces a flame retardant coating material interested in understanding the superior performance of a competitor’s product. Tetramer was asked to identify the chemical composition (type and molecular weight of polymeric binder and any additives), metals content and type, density, glass transition temperature, solids content, and possible chemistries that enabled the enhanced performance of the product. Tetramer leveraged a variety of analytical capabilities and our deep understanding of materials science and chemistry to develop a comprehensive materials analysis report for the customer.

-

Identified the chemical composition

-

Determined metals content

-

Analyzed physical properties

-

Concluded the possible chemistries that allowed the competing product to have better performance

Scanning Electron Microscopy/Energy Dispersive x-ray Spectroscopy (SEM/EDS) – provides analysis of microstructure and elemental composition.

Attenuated Total Reflectance – Fourier Transform InfraRed Spectroscopy (ATR-FTIR) – provides spectroscopic information about the types of chemical species that comprise solid or liquid samples.

Thermogravimetric Analysis (TGA) – measures weight loss as a function of temperature and can be used to identify organic vs. inorganic content, decomposition temperature, and relative mass of formulated components.

TGA-FTIR – measures weight loss as a function of temperature and simultaneous FTIR spectra of the gasses evolved from a sample while heating.

Gel Permeation Chromatography (GPC) – provides chromatographic separation of organic species extracted from the sample. Different components are separated based on their molecular weight (Mw, Mn).

Elemental Analysis – measurement of carbon, hydrogen, nitrogen, sulfur, and halogen content in a sample.

X-ray Diffraction (XRD) – provides information about crystal structure of materials and can be used to identify minerals, oxides, and compound materials.

X-ray Fluorescence (XRF) – provides ppm-concentration measurements of individual elements in a sample.

Differential Scanning Calorimetry (DSC) – measures heat flow in/out of a material versus temperature. Can provide information regarding Glass Transition, melting point, and decomposition temperatures.

Nuclear Magnetic Resonance (NMR) Spectroscopy – provides analysis of chemical environment for individual types of protons, carbons, or other atoms in a sample. This information can be used to identify what molecular species are present.

Helium Pycnometry –provides a highly accurate volume measurement for a sample of material by helium gas displacement which is then used to calculate the mass-to-volume ratio for total density.

Automatic pH Titration – measurement of total H+ ions in a solution as a direct measurement of the pH for a dissolved material.

Flash Chromatography* – a high-throughput, semi-preparative process for separating chemical species based on their relative interaction with a stationary phase (alumina or silica powder) and a mobile phase (solvent).

Solubility Testing – a solubility test was carried out to identify appropriate solvents for extracting organic compounds from the sample.

Inductively Coupled Plasma – Optical Emission Spectroscopy (ICP-OES) – atomic spectroscopy-based analysis used to measure metals content down to ppm levels.

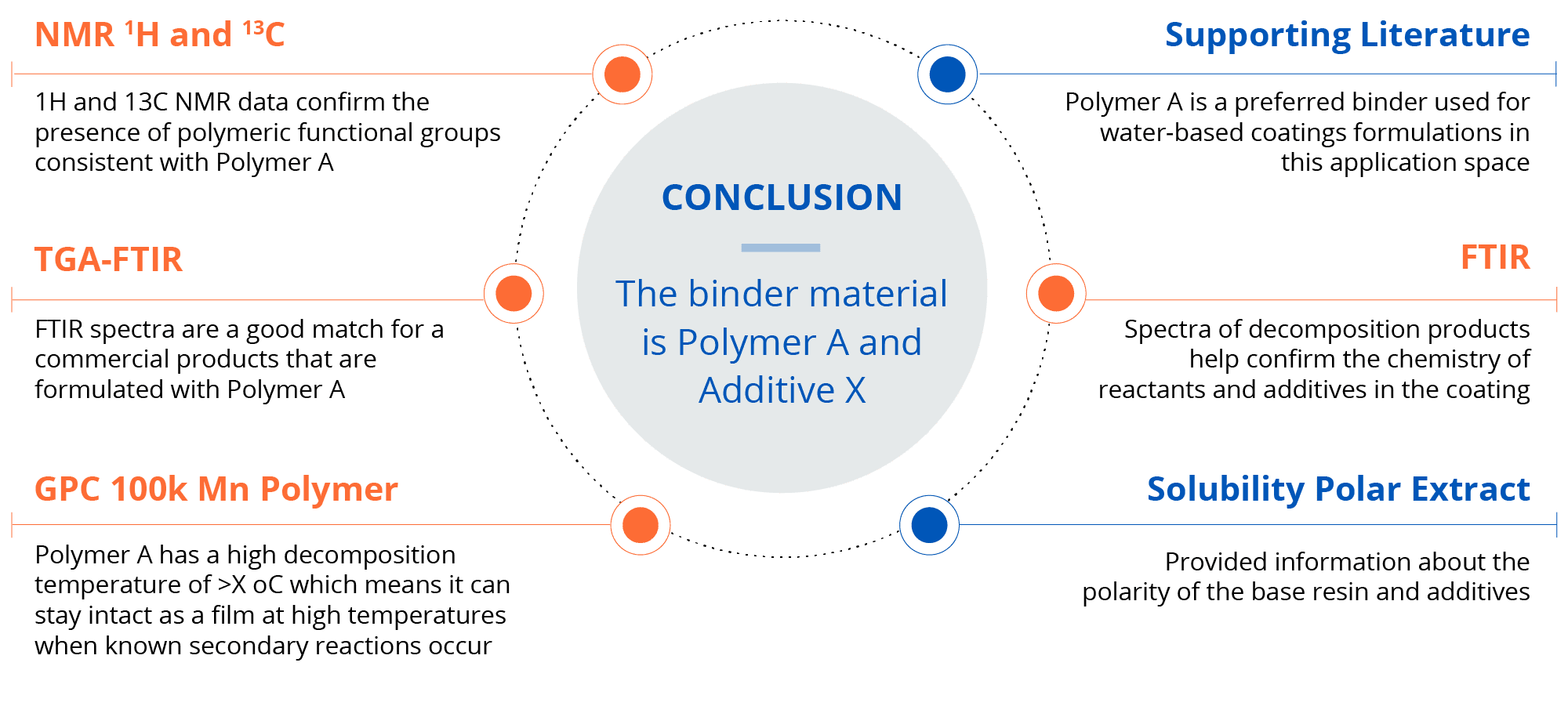

Conclusion Map Tetramer provided to our Partner