View Press Release

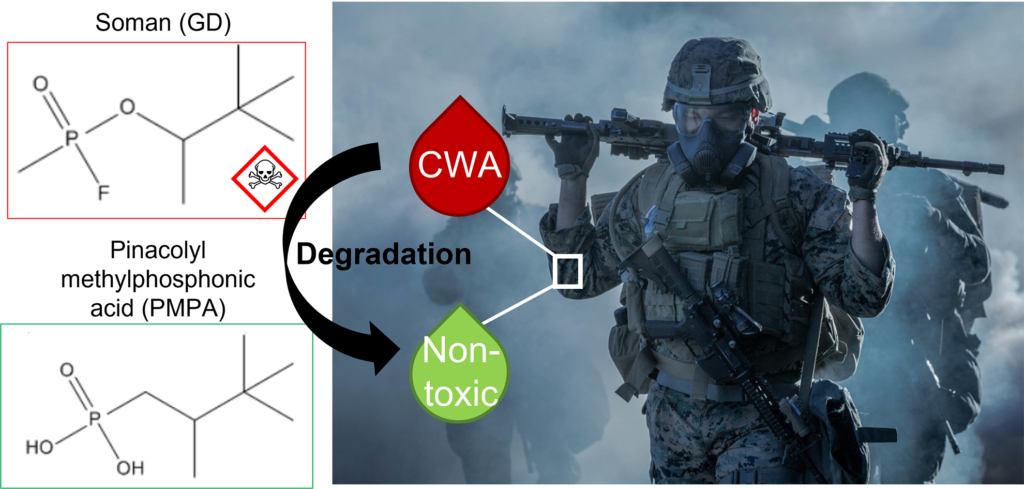

Tetramer will continue the development of a novel adsorbent material used in protective suits for soldiers that encounter chemical, biological, radiological, and nuclear (CBRN) environments under a new $1.15MM Phase II award from the Joint Science and Technology Office for Chemical and Biological Defense (JSTO-CBD). Tetramer bead technology consists of metal-organic frameworks (MOFs) that are incorporated into soldiers’ protective suits. Unlike existing carbon-based materials that only absorb chemical warfare agents (CWAs) into the suits, Tetramer materials both adsorb and detoxify CWAs into non-toxic compounds on contact.

For warfighters facing the threat of chemical warfare agents, confidence in protective gear is critical. Heather Lange, Tetramer Research Scientist said, “Tetramer’s material not only adsorbs the chemical threat but degrades it as well, significantly increasing efficacy of the suit to improve the physical safety and the psychological performance of the soldiers. This material has applications in protective suits as well as gloves, boots, and even gas masks.”

Using these beads in place of current materials is expected to better protect warfighters while also increasing breathability and comfort to enable extended use times and reduced logistical burden on forward operating units. Additionally, these materials are suitable for use in protective wear for civilian industrial applications such as HAZMAT suits.

Promising Phase I Results:

Tetramer MOF-beads developed during Phase I showed excellent initial performance in testing according to the DEVCOM Chemical and Biological Center. Dr. Stephen Hudson, Tetramer Principal Investigator said, “It’s hard to overstate the significance of the work that was accomplished in our Phase I program. In just six months, our team was able to down select, formulate, process, and evaluate a set of materials that have enormous potential for improving the effectiveness of chemical safety clothing for the military and first responders world-wide. Of course, there is plenty of optimization work to be done during Phase II and beyond, but our Phase I results provided a great launchpad and technical understanding that we’ll be able to leverage and build from moving forward.”

Moving into Phase II 2022-2024:

The Tetramer team will be partnering with a team of Chem/Bio developers and engineers as well as current PPE fabric producers like Kappler, Inc. to ensure the materials are successfully integrated into suits and that they are cost effective. A statement from Kappler, “Kappler Inc. is excited to collaborate with Tetramer Technologies LLC on Phase II of their CBD-MOF Bead Project. We believe this emerging technology will offer improved performance for chemical protective apparel designed for military and law enforcement personnel. The opportunity to collaborate with Tetramer Technologies and benefit from their wealth of research and development allows Kappler to lead the chemical protective market in introduction of new protective technologies. Our goal is to perfect CBD-MOF beads during this project and bring this solution to end users.”

Tetramer has a long history of developing materials for use in DOD applications. Tetramer CEO Dr. Jeff DiMaio said, “Tetramer’s mission on our DOD programs is to get technologies out of the lab and onto the battlefield. We are excited about the development of our CBD-MOF Beads. This technology can save lives on the battlefield by protecting the warfighter. As we move into Phase II of our program, the team is ready to do the hard work of innovation and looks forward to partnering with industry-leading partners like Kappler to fully integrate the bead technology into fielded protective suits.”

Our team is interested in connecting with other partners who recognize the opportunity to use this technology in protective applications. The MOF-bead technology has significant potential in many other applications beyond just fabrics and protective garments, and our team is well positioned to develop customized beads for these alternative uses. To connect with the team and learn more about this ongoing work, contact us here.

Kappler Inc. is a small business headquartered in Guntersville, AL. We have been protecting Military Personnel, First Responders and Industrial Workers with chemically protective clothing since 1976. Additionally, we provide custom research and development for projects requiring chemical barriers, prototype services for product innovations, contract manufacturing for product scale-up, specialty, testing services, and product specific training. Kappler is a woman-owned small business (WOSB) and ISO 9001-2018 certified.